To celebrate the launch of OrCAD X and the fact that Cadence has included the very popular CIS option in their new OrCAD X PCB design suites we have decided to make our training course free to help customers leverage this new technology as they begin to adopt OrCAD X.

If that’s all you need to know you can access the free course here: OrCAD Capture CIS and CIP Training | EMA Design Automation (ema-eda.com) (just need to register…which is also free)

If you are looking for more information about what OrCAD CIS and CIP are and what they do for you read on…

What is CIS & CIP?

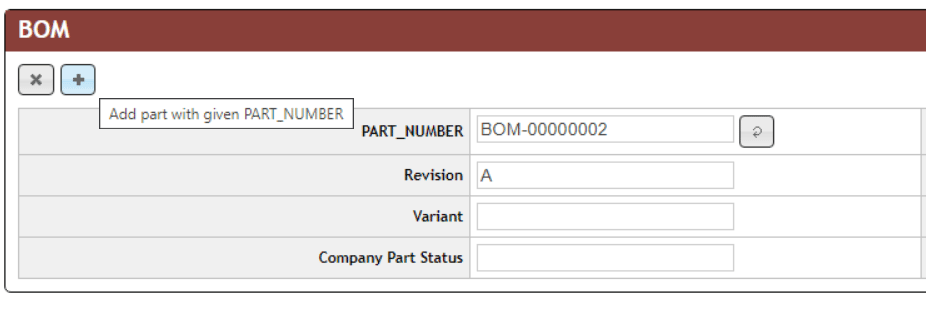

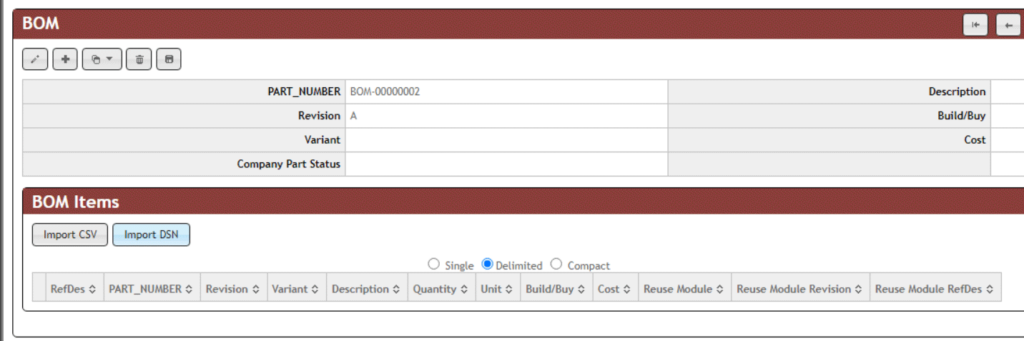

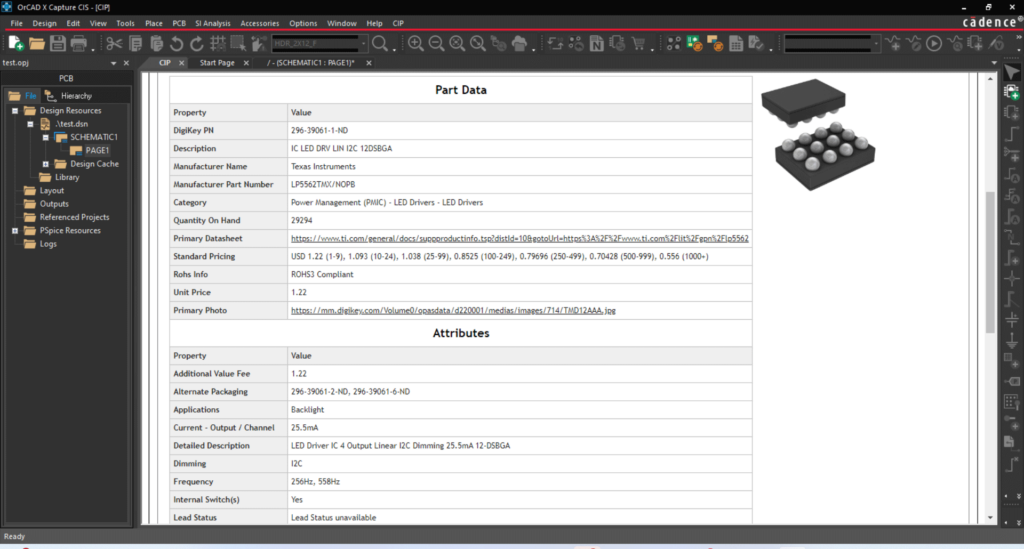

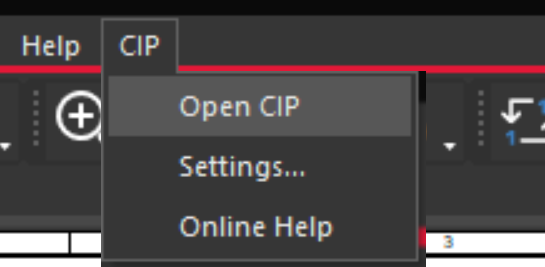

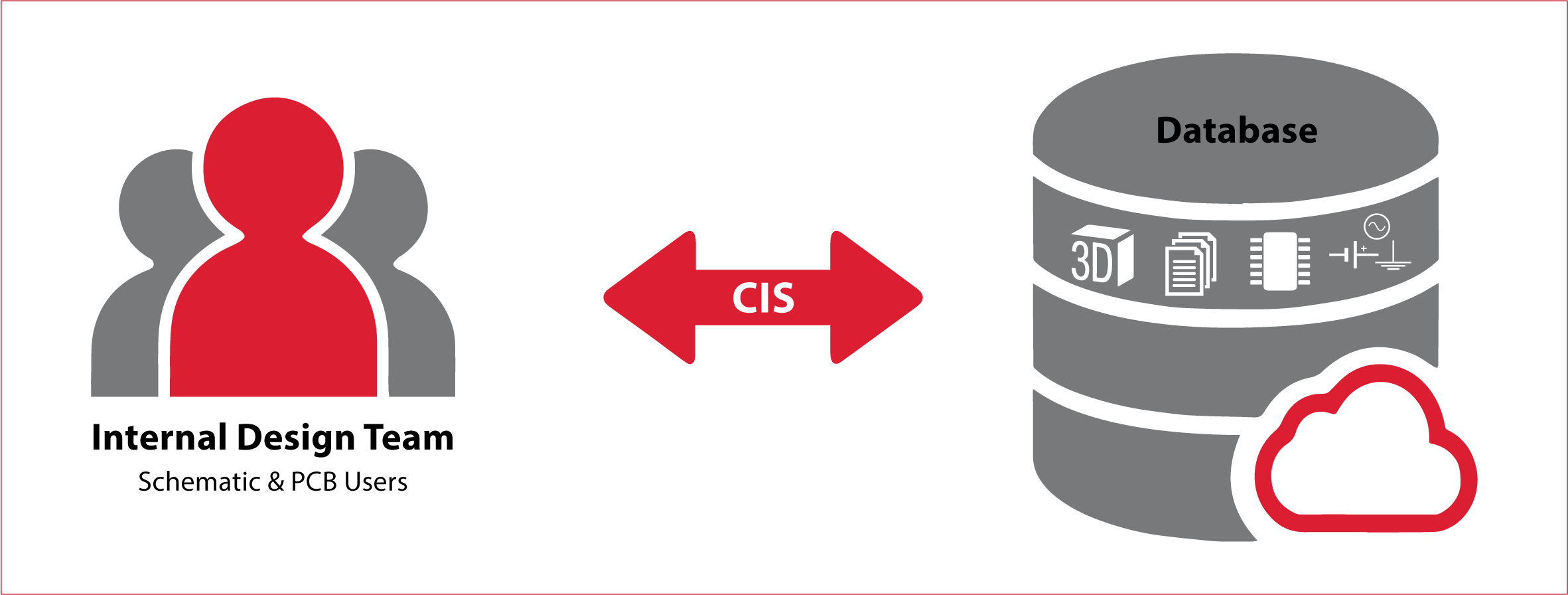

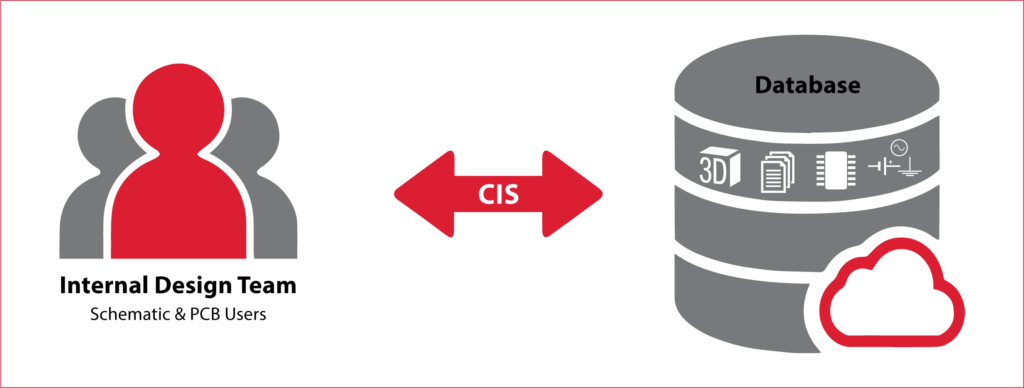

OrCAD CIS and OrCAD CIP stand for Component Information System and Component Information Portal respectively. What they do is enable your OrCAD environment to store, source, and manage your part library leveraging a relational database. This provides several significant benefits.

CIS enables the ability to connect OrCAD to a database which allows you to:

- Integrate and centralize your component data

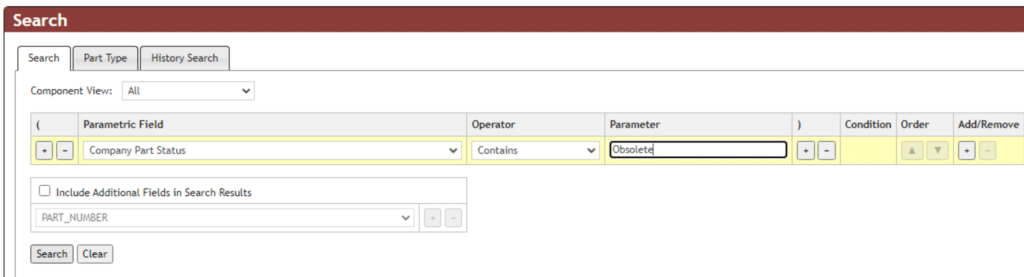

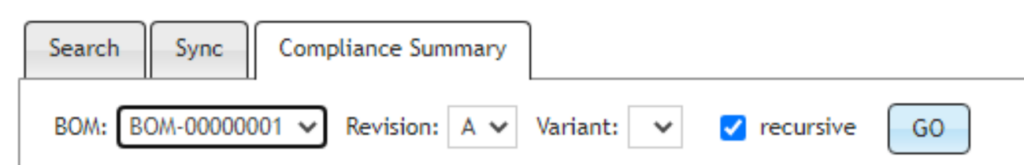

- Provide parametric part search capabilities

- Preview symbols and footprints before use

- Templatize and configure BOM generation

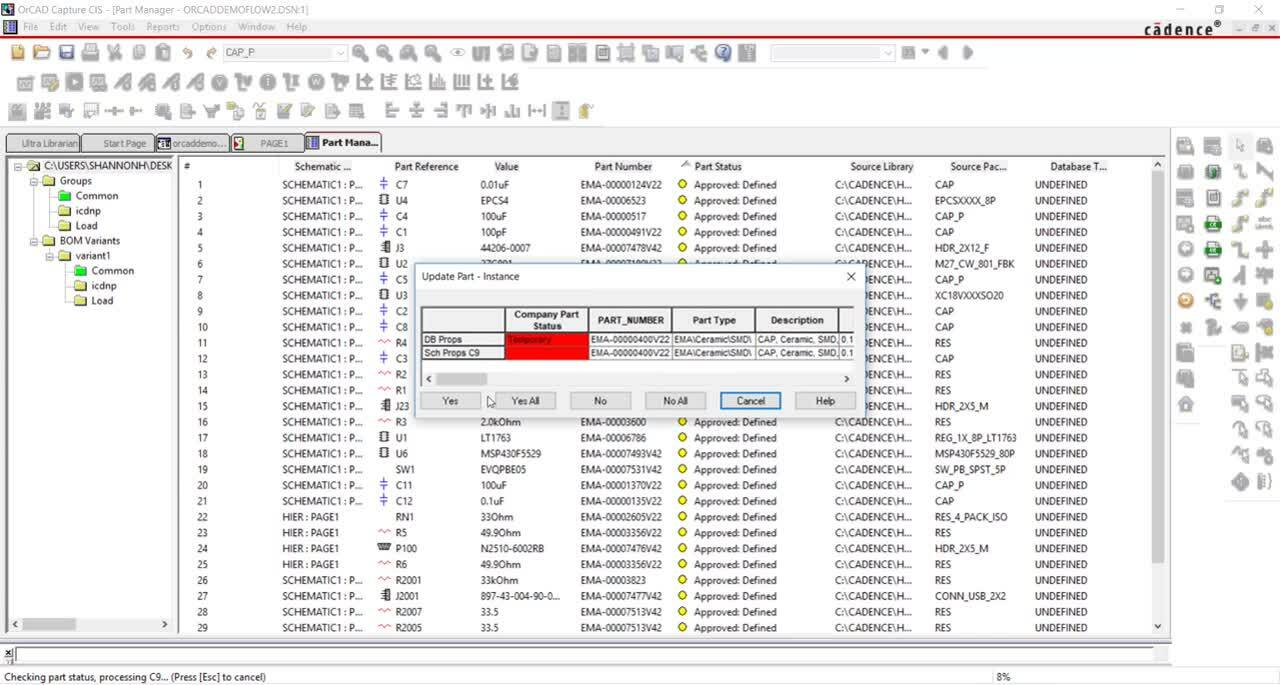

- Integrate part management

- Support design variants

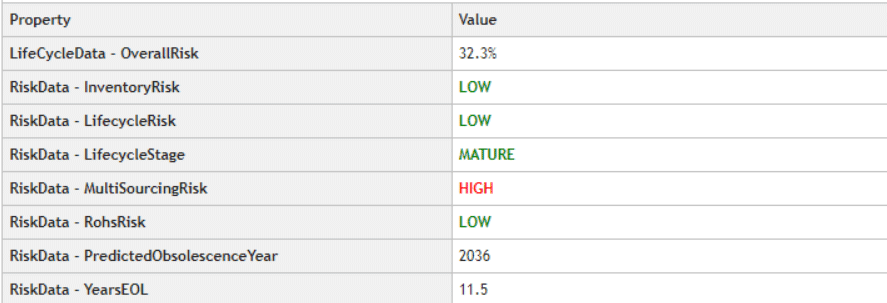

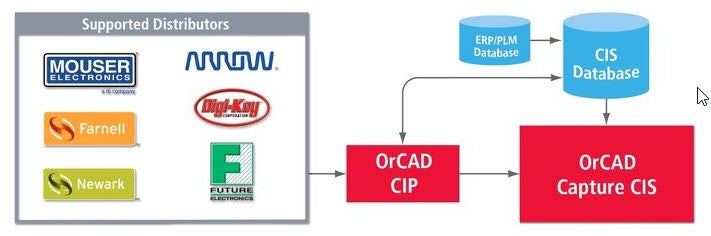

CIP provides the means of populating, managing, and automating this database so you can leverage it to the fullest including:

- Search and import distributor parametric data for your parts (as well as keep this data updated automatically)

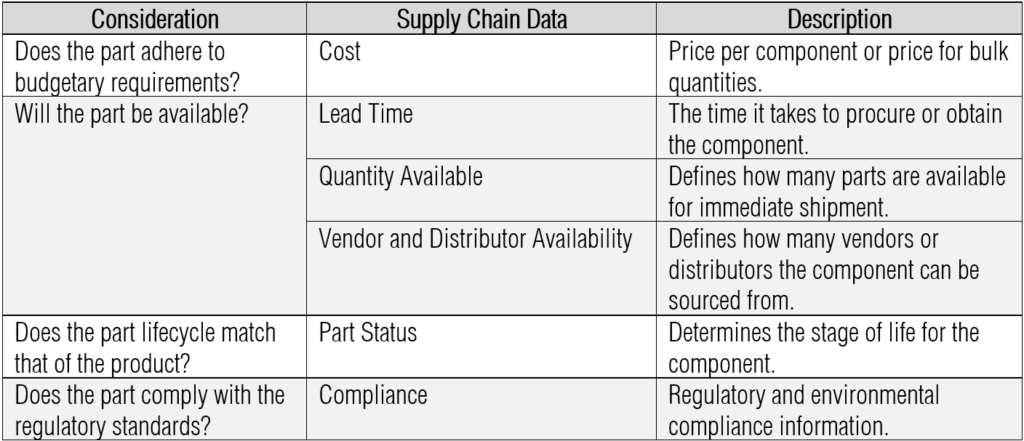

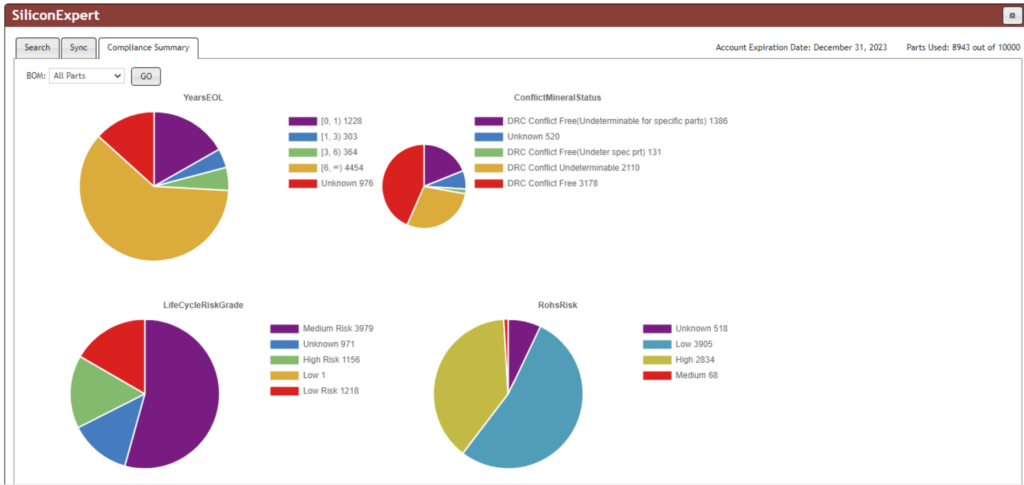

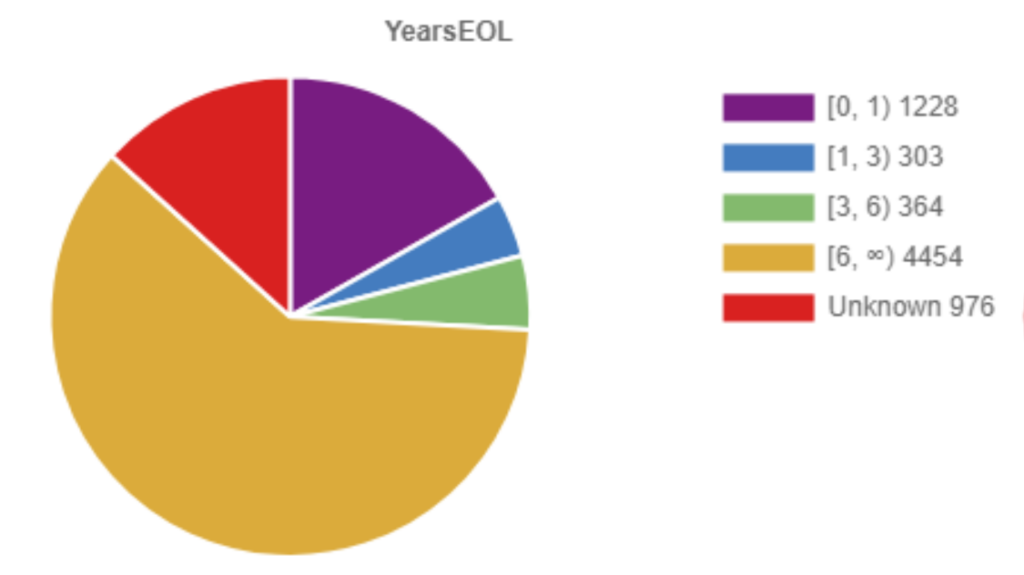

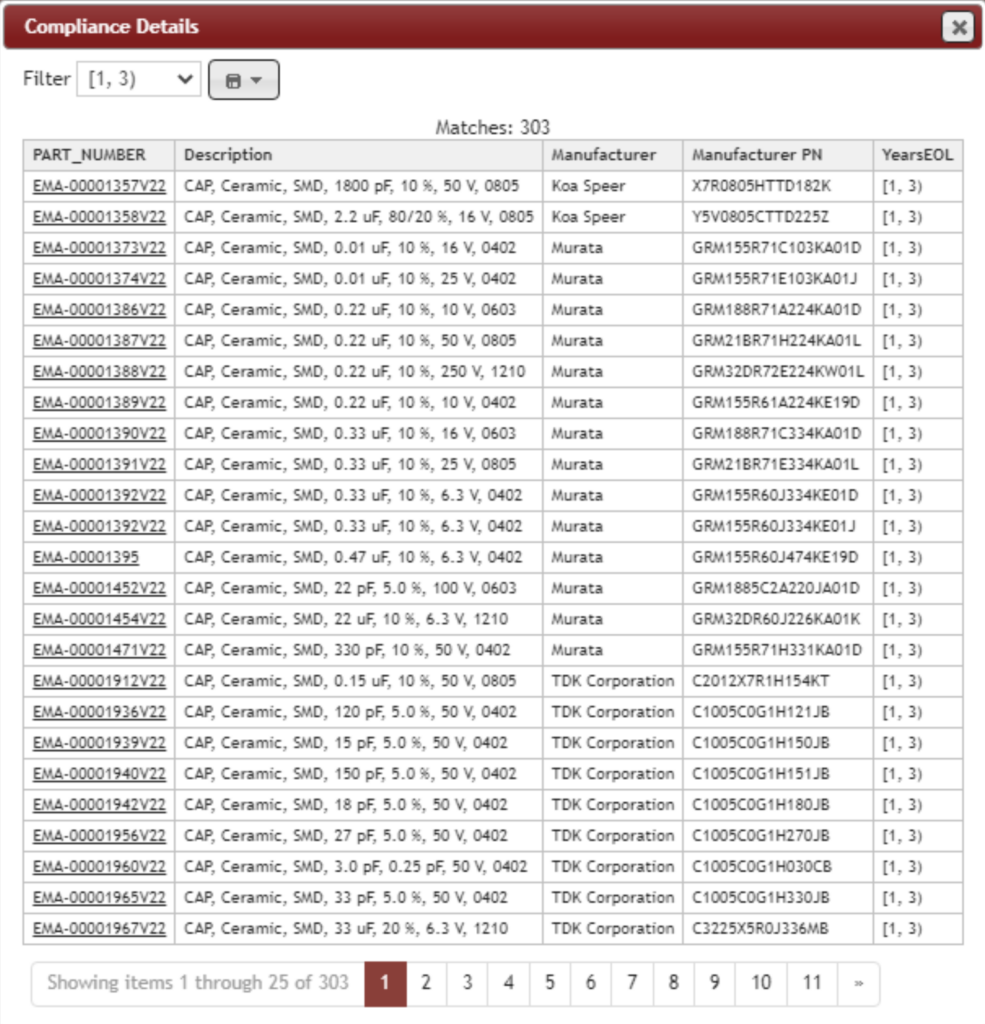

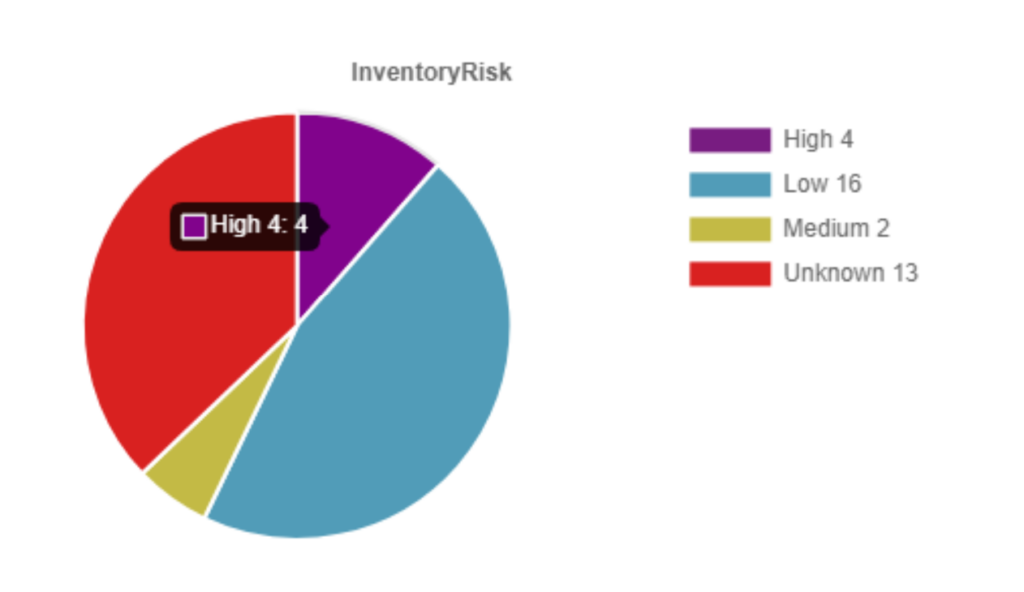

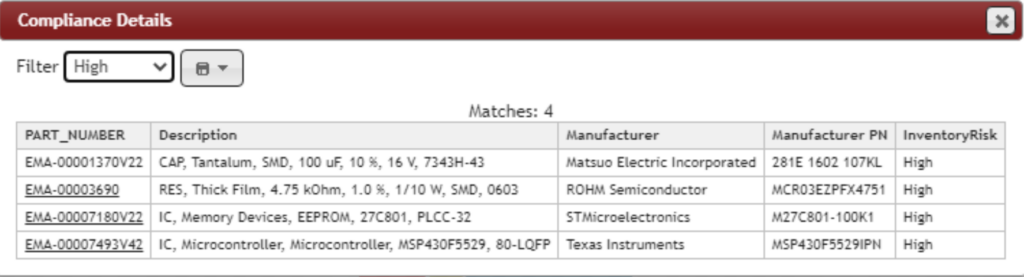

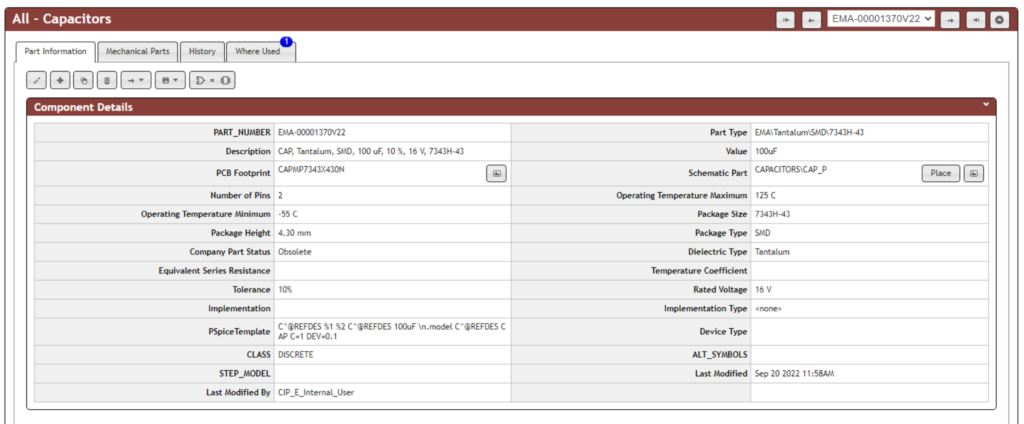

- Connect supply chain data such as lifecycle, risk, cost, and compliance so you can easily make supply chain driven part decisions

- Integrate with CAD library services such as Ultra Librarian to eliminate the need to build CAD models

- Track changes to part status and other key metrics and trigger notifications off these changes

- Identify multiple sources for parts to ensure availability

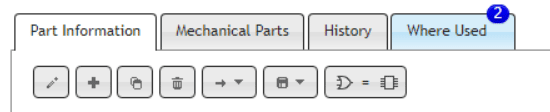

- Leverage functions like ‘where used’ to quickly see the impact of part changes across all your designs (past and present)

- Manage users and roles to ensure data integrity and traceability

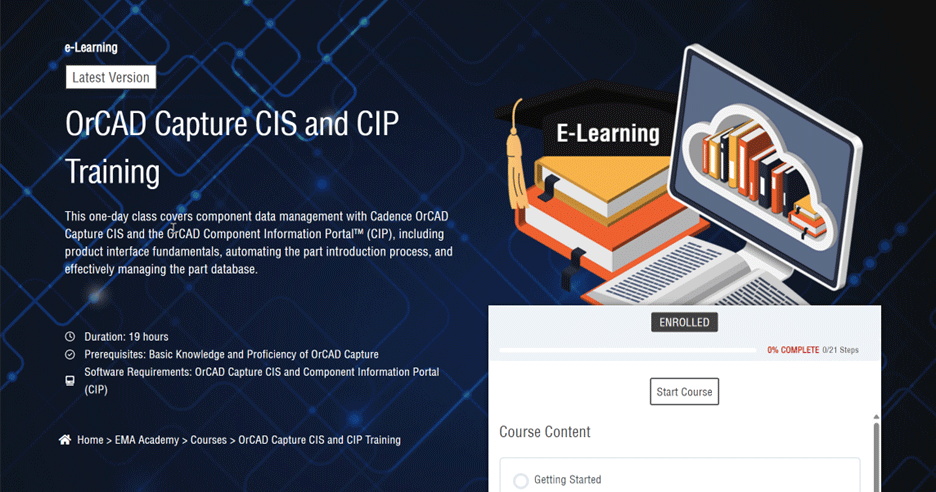

As you can see this is quite a powerful combination providing comprehensive part and library management capabilities directly inside the OrCAD design environment. These new capabilities mean there are now new ways to access and leverage your parts that you may not have been used to in OrCAD.

The OrCAD CIS and CIP training will help users get acclimated quickly to how to leverage these tools to their fullest.

Why Are We Making This Course Free?

This course was originally created based on requests from customers who had chosen to adopt this managed library flow. While this course has been available for a while, it was only applicable to those that owned these options for their OrCAD software. With CIS being made a part of the standard OrCAD X suite configurations this meant a lot more users were about to get access to this way of managing their libraries and data and we wanted to make sure this was a smooth transition for all users. Making this course free will (we hope) help users adopt CIS and the managed library approach which we have seen through years of experience means a more efficient and effective design process, and a happier customer.

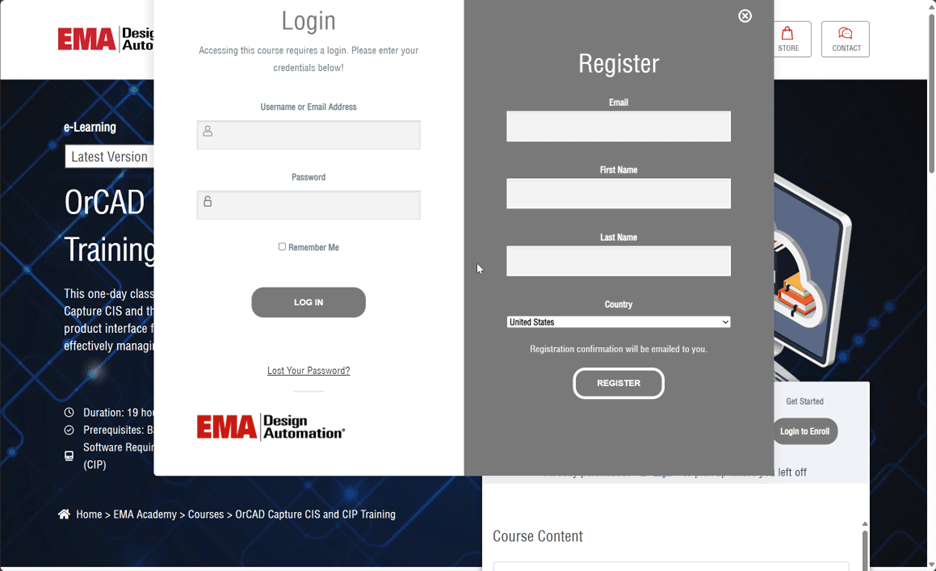

How to Access the OrCAD CIS and CIP Training?

If you didn’t see above, the OrCAD CIS and CIP training course is part of the EMA Academy and is available to all users who have an active account (which is free) or who register for one. If you need to you can register right on the course page itself, just select login to enroll and complete the quick registration process.

We hope customers will take advantage of this free training opportunity to help them learn how to leverage one of the key new features in the OrCAD X release.

Additional information and details are available in the OrCAD Capture CIS datasheet.

Additional information and details are available in the OrCAD Capture CIS datasheet. Find the version and licensing agreement that best fits your needs and budget.

Find the version and licensing agreement that best fits your needs and budget.